Start at the drawing board

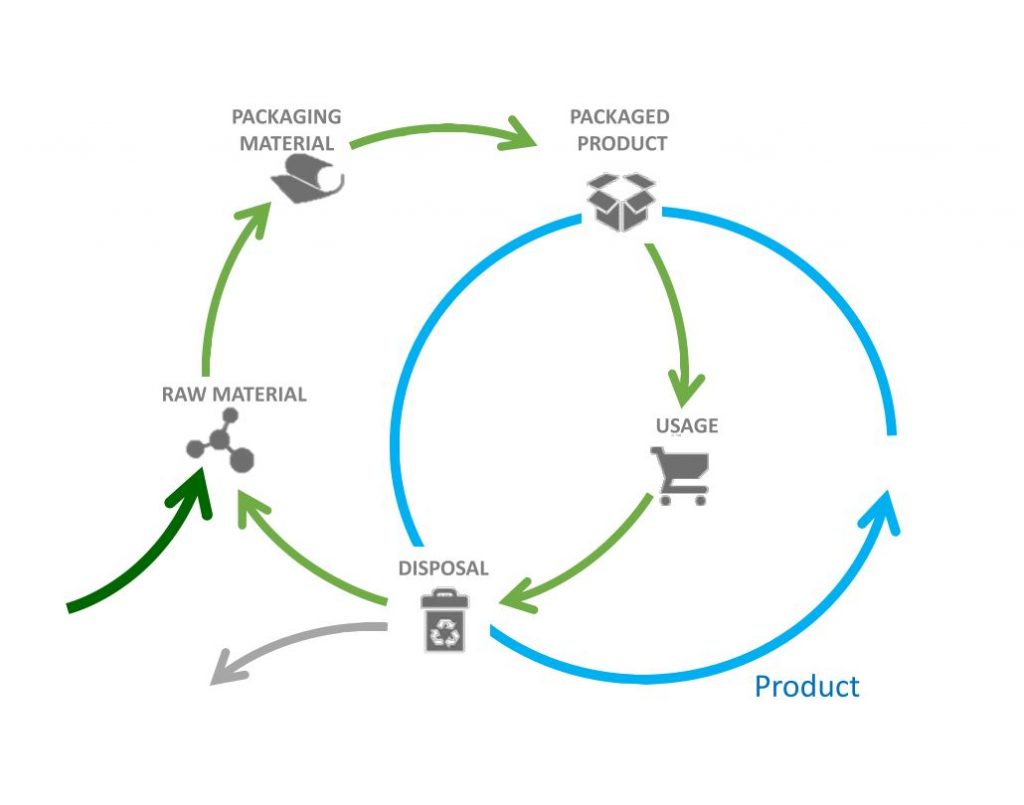

The most efficient way to use sustainable packaging is to take the environmental impact of a product-packaging combination during its entire lifecycle – from production, to usage, to disposal, to raw material – into account during the design stage. This often results in innovative product and packaging solutions that are ultimately profitable, both in terms of their environmental impact and in terms of cost reduction and added value.

Choose an integral approach

Developing sustainable product-packaging combinations calls for an integral approach, because you have to make choices from a variety of perspectives. Think for example of your organisations or brand’s policy and strategy, your customers’ wishes and needs, and the packaging process. The KIDV model Five perspectives on sustainable packaging®, which can be found on this website, can help you with this.

The output of sustainable product-packaging combinations

- More environmental advantages because of a reduced environmental impact. By reusing and recycling packaging materials, you can make raw materials last longer and make more effective use of them. This reduces the environmental burden and CO2 impact of the process.

- More value because of more and satisfied customers. Sustainability is a factor taken into account during the purchase process for a growing number of customers. Furthermore, customers get excited about well-designed and compact packaging materials that do not create excessive waste and are easy to separate during disposal.

- Ultimately, higher profits because of lower costs. Innovative and sustainable packaging solutions will ultimately lead to innovation in the value chain, with fewer raw materials used and fewer products lost. As a result, you need less material and your production and logistical costs will go down.